In the interwar period, various European countries saw attempts to turn the building of houses from a craft-based endeavor to industrialized machine production. One of these attempts was the Oceľový dom [Steel House] company in Bratislava, formed in the late 1920s to produce prefabricated steel-frame houses. Drawing upon strong ambition and powerful industrial backing, and emboldened by its early successes, the company nonetheless soon began to struggle and eventually was forced to leave the scene. Far from achieving the widespread impact it had envisioned, Steel House remained only a short-lived episode in the turbulent development of construction in the interwar period.

Introduction: The Prefabricated Dream

For the greater part of the 20th century, a central idea occupying architects’ minds was that of prefabrication. If the automobile, or the teapot, or the shoe could be mass-produced in a factory, delivering the same quality as the best craftsman but at a fraction of the cost, then so too, the idea goes, could the house. Inspiration arose from a powerful image: Henry Ford’s Model T cars leaving the assembly line by the thousands, turning what had once been a luxury product into an accessible commodity and raising the material living standards of the masses.1 The Modernist avant-garde saw this image and sought to transplant it into architecture. Indeed, a large part of the “heroic” phase of the Modernists’ work – from Le Corbusier’s Citrohan to Frank Lloyd Wright’s Assembled Houses to the many attempts at mass housing by Walter Gropius and Ernst May – can be understood in this context.2

For the Modernists, the allure of mass-produced prefabrication was multifold. First and foremost, they saw it as the logical solution to the housing crisis developing in Europe after the first World War, and more broadly, to key societal issues on a broader scale, as echoed in Le Corbusier’s famous aphorism, “Architecture or Revolution”.3 More directly, they were also fascinated by the aesthetics of the factory and the mass-produced object – the objet type – marveling at images of airplanes, ball bearings and grain silos. Mauro Guillén hints at a more general obsession with the principles of industrial scientific management – efficiency, rational organization and reduction of waste – which the Modernists translated into the machine aesthetic.4 Additionally, as Herbert Gilbert suggests, they might have also been allured by prefabrication as a holistic system, a manual, a sort of modern substitute for the classical orders they had so vigorously rejected but which provided the architect with a secure framework to think in – and which they now needed to replace.5

Houses without Architects

Still, the practice of prefabrication long predates the Modernists. Before their utopian visions, there had been roughly a century of development of prefabrication, motivated not by desires to change society but by pragmatic needs and business interests. Already during the British colonization of Australia, South Africa and Canada during the early 19th century, pre-cut timber frames in standard dimensions were shipped from England to be quickly assembled on site.6 In the 1830s, this developed into one of the first prefabricated building “products”, the Manning Portable Cottage, made by the carpenter John Manning.7

In the USA, the system that defined much of the country’s built environment was the lightweight timber “balloon frame”, developed in Chicago around the same time that Manning presented his cottage.8 While not necessarily factory-made, the balloon frame used standard dimensions and allowed for a quick, dry, on-site assembly. By the turn of the 20th century, companies such as Sears and Aladdin began to offer mail-order houses with balloon frame construction. The posts and joists arrived on a railcar, sorted and numbered, and accompanied by the necessary secondary components like windows and nails.9 These houses were traditional in appearance, almost banal, designed not by a visionary architect but instead a collective of anonymous specialists. Nonetheless, they offered much of what the Modernists would dream about some two decades later.

Apart from wood, another material lent itself especially well to prefabrication: iron, or more precisely steel. The industrial age allowed for fine precision steel manufacturing as well as a lower cost. While steel was still a more expensive option than traditional materials, it compensated by its durability and its very favorable weight-to-strength ratio.10 The first truly prefabricated steel dwellings were rather modest: temporary shacks set up by colonists, miners and seasonal workers on the frontiers, made of corrugated metal sheets.11 Soon, however, more sophisticated systems emerged which aspired to the status of a permanent dwelling. The environment was especially fruitful in Britain, which had both a developed industrial base as well as incentives from the government. Due to a combination of material and labour shortages and a lack of housing, the British government incentivized building with non-traditional materials after World War I.12 Many patented building systems emerged, several of which were based on steel. Some used timber frames with steel cladding, others steel frames with steel or concrete cladding, and yet others load-bearing steel panels.13 But even though more than 10 000 of these steel-system houses were built,14 by the mid-1920s they had reached their zenith and were once again overshadowed by traditional masonry. The government saw the new technologies only as temporary solutions, and so did the public, which never let go of the image of the solid, durable masonry house.15

The Böhler System

This British development was observed with keen interest in another country: Germany.16 Like Britain, Germany was an industrial country and suffered from a lack of housing, creating both demand and supply for prefabricated construction systems. Yet unlike in Britain, there existed a Modernist avant-garde movement in Germany which hoped to take part in, or in fact direct this development. As early as 1910, Walter Gropius wrote a letter to Emil Rathenau, the head of the corporation AEG, outlining a proposal for a prefabricated housing system.17 For Gropius, the keyword in his vision was variability – that is, prefabrication not of entire houses, but rather standard components which allowed for customization of the whole.18 Gropius hoped for a collaboration between the architect and the industrialist, each with their own motivation but united in the desire to see the factory-made house succeed. He found no luck with Rathenau, but other such efforts were taking place. Sometimes they involved visionary architects, but more often than not, were motivated purely by business.

And so, just as in Britain, many novel building systems emerged which attempted to bring the benefits of the assembly line into house construction. Several were based on steel, which was supported by steel-making companies looking to induce demand.19 Most were named after their proprietary company: Wöhr, Stahlhaus, Braune & Roth; the last one perhaps most famous as it was the system chosen for the experimental 1926 Bauhaus steel house in Dessau by Georg Muche and Richard Paulick.20

One such novel system was the Böhler system. Technically not developed in Germany but in Austria, it was one of the few building system that in fact was designed by an architect – Alfred Schmid.21 Soon after the war, Schmid was employed by the Austrian steel company Gebrüder Böhler, and devoted himself to industrial rationalization of building methods, eventually even rising to the post of director.22 In 1927, Schmid published an article about the steel-based system he had developed in the years prior. His design was rather simple: U-shaped steel posts and joists spaced 1 m apart, the walls clad with Heraklith boards and plaster on the outside and steel panels on the inside.23 In his article, Schmid talked at length about the economic benefits of the prefabricated system – the potential of rapid assembly in any weather, the ability to utilize unskilled labor and the good weight-to-strength ratio of steel. On the technical side, he emphasized that the 15-cm thick walls of his system were equal to a 60-cm brick wall in terms of thermal insulation, a claim that in retrospect seems somewhat exaggerated.24 Similar language was used in a 1928 book about Austrian building, which noted Schmid’s system; additionally, this text also underlined the longevity of the steel skeleton thanks to various supposed anti-rust measures.25

The Böhler company exhibited two of its steel houses in the 1926 exhibition Wien und die Wiener.26 They were rather traditional in appearance, but seemed to have secured commercial success. Böhler opened a branch in Berlin and exhibited there in 1931 and 1932. In 1933, plans were discussed to build a colony of 2500 Böhler houses in Germany, but the ongoing Depression and the Nazi regime’s military ambitions made the use of steel for construction economically unviable. Even then, some houses were exported to Palestine.27 Though mostly forgotten today, Alfred Schmid and the Böhler company represent one of the rare cases where the Modernist dream of collaboration between architect and industrialist actually succeeded – if not for groundbreaking progressive architecture, then definitely for market viability and delivering the promised product.

“The First Steel House in Czechoslovakia”

Not far from Vienna, Slovak and Czech industrialists faced the same prospects as their Austrian and German counterparts. With an equally urgent need for housing, there was potential for a novel system to succeed. Certainly, there had already been experiments with non-conventional materials in Czechoslovakia, such as various patented cinder blocks28 or the diatomite-based Calofrig, which for a time became the lodestar of the Modernists’ technical visions;29 and of course, the reinforced concrete skeleton was a well-established system by the late 1920s. Yet despite the young republic’s advanced steel industry, steel remained untested, especially for residential buildings.

Public opinion was split on the issue. One can find newspaper articles praising the British and German steel houses, wondering when Czechoslovakia too would throw away conservatism, accept the benefits of industrial production and “build more cheaply.”30 Others were cautious, admitting that steel houses could indeed be built quickly but much more experience would be needed to consider them seriously.31 And some were uncompromisingly skeptical, pointing out that the British steel houses were always meant to be temporary and could never compare with the tried-and-tested masonry;32 this was, as we saw, the opinion that ultimately prevailed in Britain.

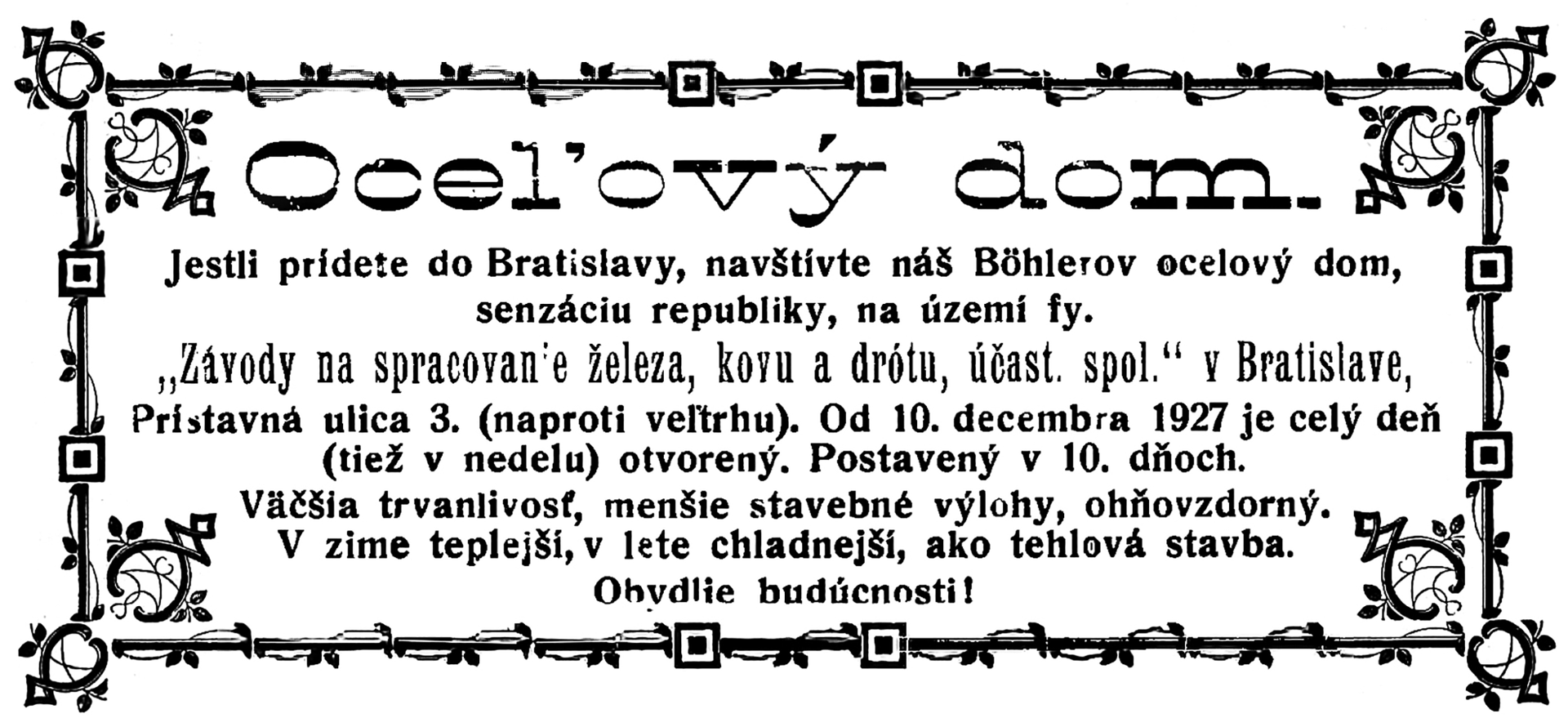

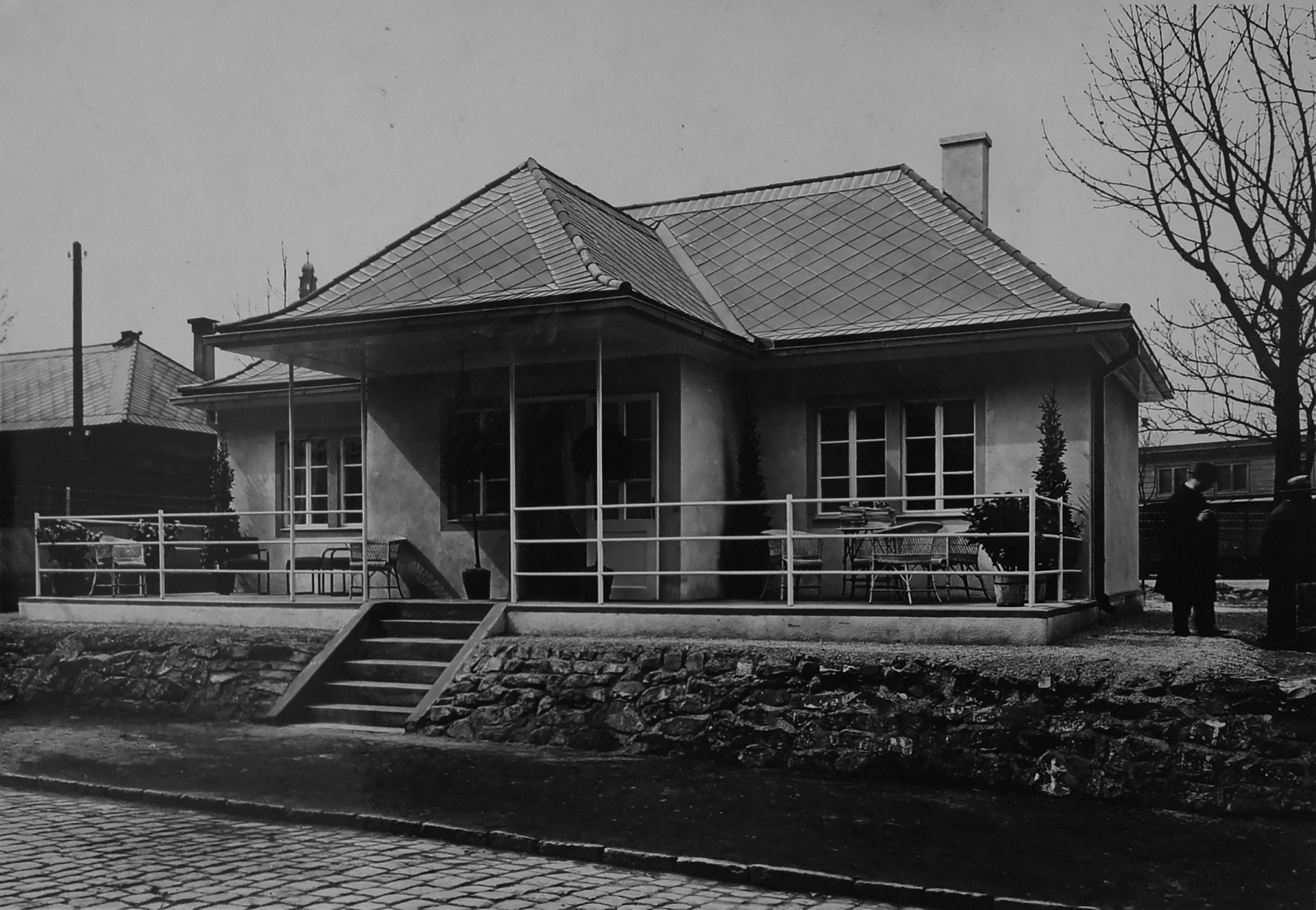

The first pioneering attempt to try and break this stereotype emerged in Bratislava. The Metal and Wire Processing Works Company [Závody na spracovanie kovu a drôtu], which had a factory near the city harbor on Prístavná Street, decided to play it safe: instead of attempting to develop a new system, it licensed the promising Böhler houses.33 In December 1927, the Metal and Wire Works built a Böhler house as an exhibition prototype on its factory grounds. The house was small, with only a kitchen, two rooms and a cellar. Intense advertising efforts were launched, and the house stirred considerable publicity. At least 10 different newspapers printed repeated ads and short articles inviting the public to visit the house,34 touting it as “the first steel house in Bratislava” and even “the first steel house in Czechoslovakia”. Echoing the rhetoric of Alfred Schmid, much emphasis was placed on the speed of its construction, which supposedly took less than 14 days, and the high quality of thermal insulation, undoubtedly because of the skepticism rooted in the public. The cost of the house was estimated to be around 40 000 Kčs, though larger, more luxurious models were also promised.35

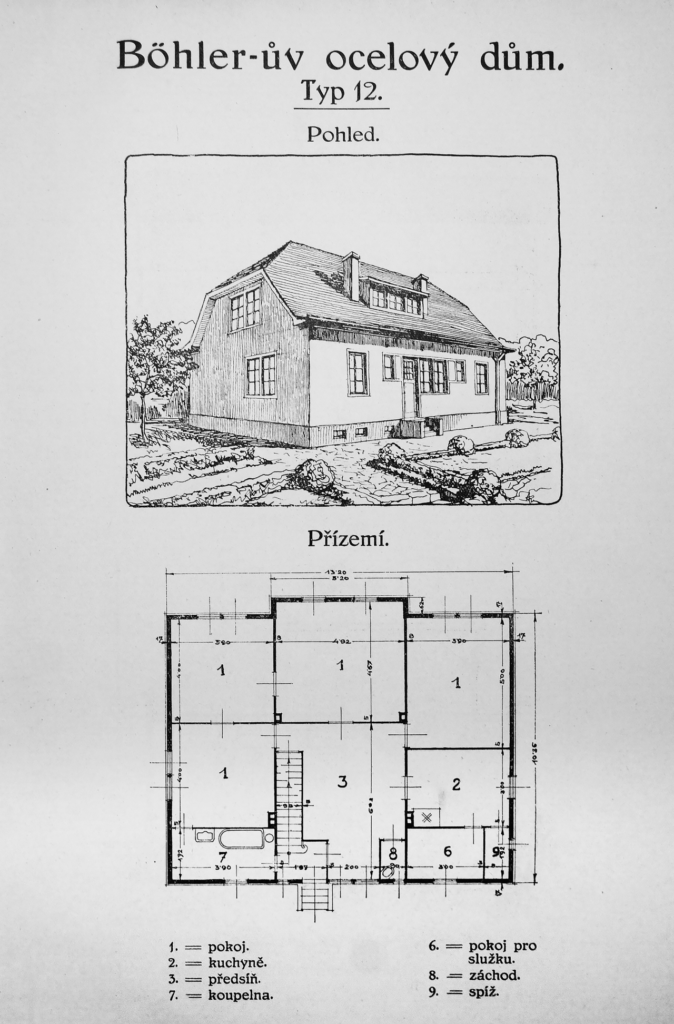

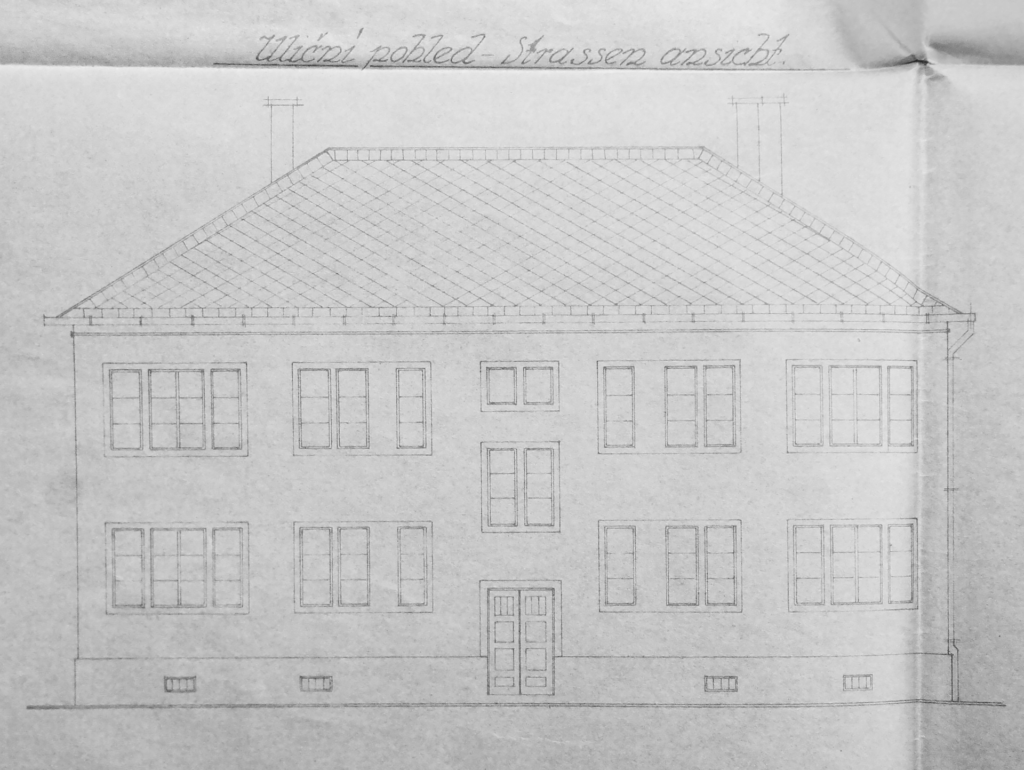

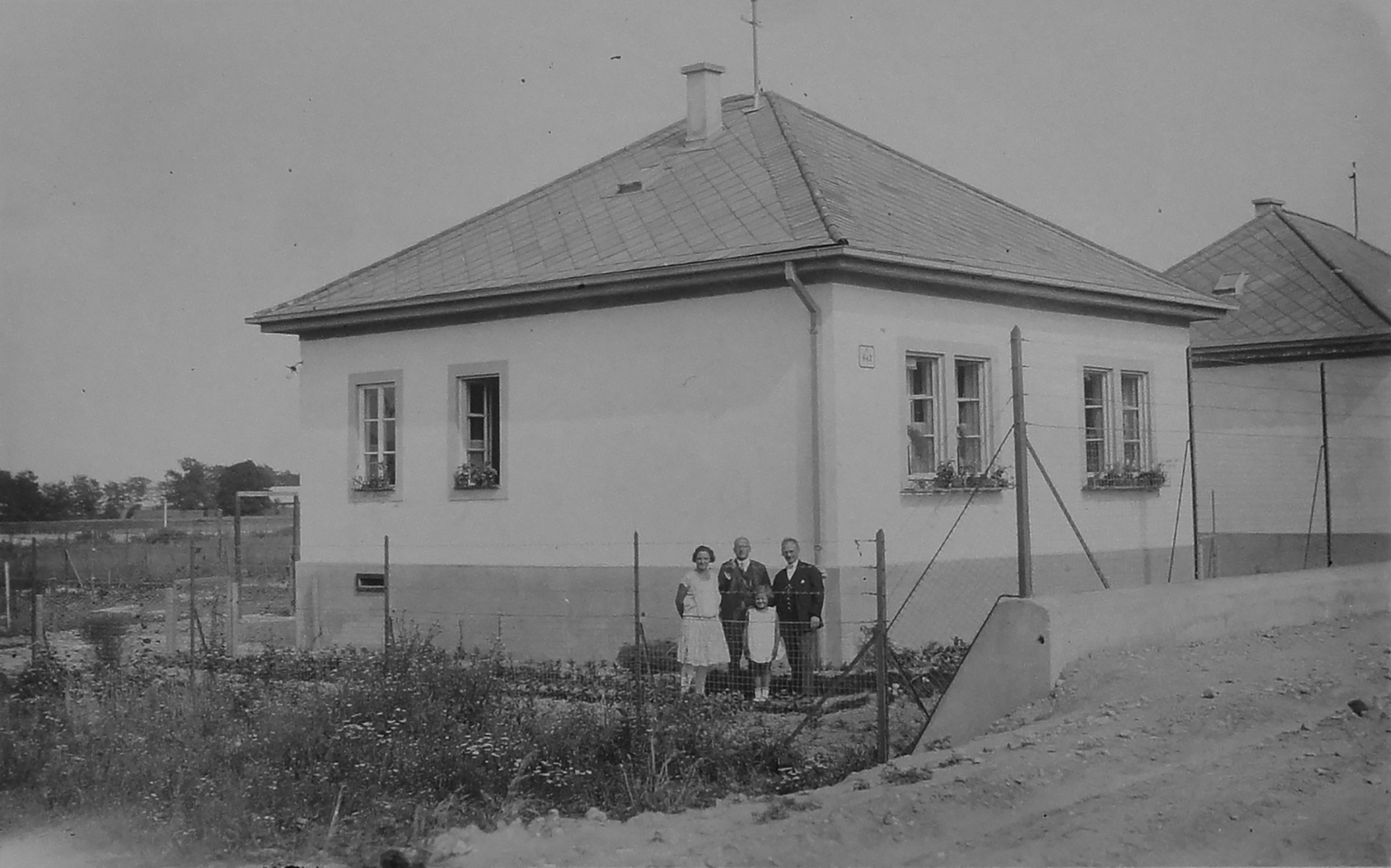

The reaction from the public seems to have been encouraging enough that some 5 months later, in April 1928, another exhibition house was built: this time in Prague, near the (since demolished) Těšnov train station. Just as the previous one, this house was also heralded as “the first steel house in Prague.” The second house was slightly more luxurious, featuring alsoalso two, but more spacious (to avoid making the impression it had 4 rooms – it had 2 but larger) in addition to a kitchen, bathroom and utility rooms. However, it came with a steeper price tag of 70 600 Kčs.36 Once again, ads were printed and articles written, more or less repeating the same points as before.37 Both houses were a far cry from Modernism, featuring a heavy, overhanging hipped roof and small windows with decorative grilles. The machine-made factory origins of the construction were entirely camouflaged, with only the sleek steel columns supporting the patio roof hinting at what was going on under the skin. No doubt this was intentional. If the consumers were skeptical about steel houses, making them look strange and futuristic would do little to dispel their distrust. On the other hand, giving the houses a conservative appearance could convince buyers that although novel, the houses would seamlessly fit into the reliable tradition everybody knew, loved and respected.

This was likely also the reason why none of the leading avant-garde architectural journals paid any attention to either steel house, even though, in their quest for industrialized building, one would assume they would have.38 The only architectural publications that took note were Architekt SIA, at the time still somewhat conservative in its focus, and Stavební rádce, which was oriented towards a broader audience than just architects. Both briefly described the location, construction and cost of the house.39 The Metal and Wire Works’ Böhler houses were also featured in a peculiar 1928 self-help book for prospective builders; the author showered them with much praise, emphasizing the benefits of dry assembly, the strength of steel, hygiene, good insulation and, echoing Gropius, the variability that the standardized system afforded.40

Oceľový dom – the Steel House Company

As the exhibition houses were successful enough, and the future seemed promising, the Metal and Wire Works Co. began looking for business partners to expand its operation. In Germany, the steel industry was naturally excited about the prospect of mass-produced steel houses, and Czechoslovakia was no different. After some negotiations, partners were found in the Coburg Works [Coburgove závody], which owned steelworks in Slovakia, and the Živnostenská Bank. In late 1928, the trio entered a joint agreement to establish a company with the purpose of selling steel houses, the Oceľový dom company.41 But acting behind the scenes was another powerful agent: the Mining and Metallurgical Company [Báňská a hutní společnost], a steelmaking giant which owned several mines and factories in the Silesia region. The aforementioned bank was its majority shareholder,42 and in turn, in 1929 the Mining and Metallurgical Co. became the majority shareholder of Coburg.43 Archival papers additionally show that Otokar Kruliš-Randa, director of the Mining and Metallurgical Co., was involved in the founding of Oceľový dom from the start.44

Headquartered in Bratislava, Oceľový dom started with a generous capital of 3 million Kčs,45 and was closely personally interconnected with its founding companies. For example, the director of Oceľový dom and the director of Coburg were one and the same,46 and additional names coincided in the management boards of both companies.47 In its founding chart, the stated goal of the company was “the construction and appreciation of steel houses, as well as the conduct of all related business.”48 With powerful backing and considerable wealth, Oceľový dom set out to work.

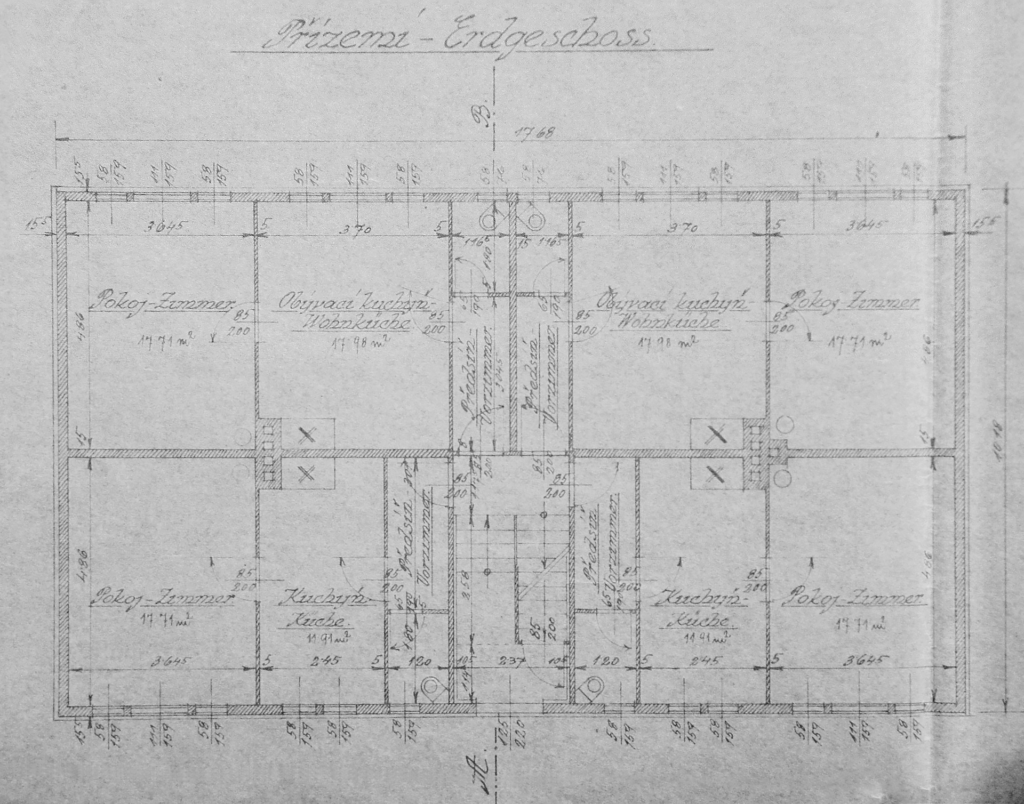

The first task the company prioritized was deciding on the specific types of houses to offer and working out their plans. This was closer to the “complete product” approach of the American catalogue houses than to the universal kit of parts that Walter Gropius envisioned. There is a mention of an architect, a certain Mr. Keck, allegedly sent by Böhler, who was employed in connection with this task.49 At first, the Metal and Wire company offered 12 types, most of them single-story family houses of varying sizes with prices ranging between 32 to 150 thousand Kč.50 Later plans by Oceľový dom itself contained 20 types in total, but this time, several of them were two-storey apartment houses with up to 4 small flats per floor.51 Notably, all of these buildings were quite conservative in appearance; apart from one flat-roofed exception, they all had steep hipped roofs, modest window openings divided into small glass panes and spartan facades leaning heavily towards classical symmetry. Clearly, they had no ambitions towards changing the taste of the general public; rather, they wished to accommodate it to the greatest possible extent.52

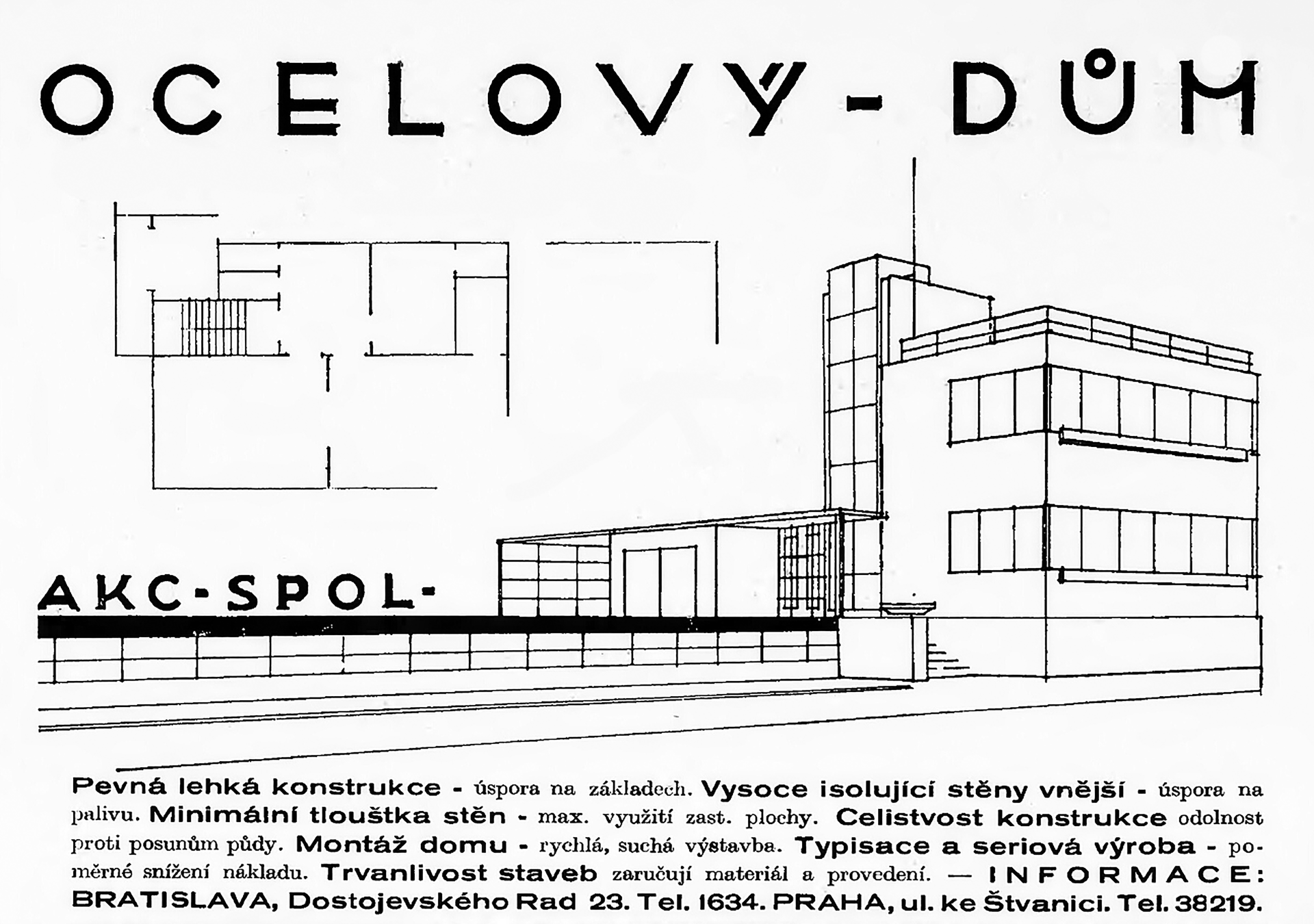

Next came advertising. Some 15 000 advertisement brochures in total, in Slovak, Czech and German, were planned for print,53 though disappointingly none of these brochures survive in any of the company’s archives. There were also ads in several newspapers. One example, a lengthy “report”, was published in a Hungarian-language newspaper in Prague; it took the form of a journalist touring a steel house with a company representative and enthusing over what he saw. He couldn’t believe the house was made of steel and Heraklith boards, since it looked just the same as all the other houses around; but despite that, it offered much more warmth during winter and a pleasant cool during summer, as the representative assured him with a kind smile.54 Another was written by an engineer, Jan Tille – who also held a seat on the Oceľový dom management board, placing his “expert opinion” in a conflict of interest.55 Small ads also appeared in several journals, including the previously mentioned Architekt SIA. This one was noteworthy, since it depicted a building much unlike what Steel House was actually selling: a sleek, uncompromisingly Modernist structure. Clearly, the company simply offered potential customers whatever they wished to see: one thing for the general public, and another for the architects. After all, style made no difference in the accounting books.

With advertising taken care of, Oceľový dom envisioned ambitious plans. A branch office was opened in Prague, for which the progressive architect Vladimír Weiss was hired. He was tasked with conducting business, but as far as the contract mentions, not with actual architectural work.56 In other cities, there were no direct offices, but plans were made for licensing arrangements with local builders. These included Olomouc and Moravská Ostrava,57 and Žilina and Košice in Slovakia; in the latter city, arrangements were discussed with the builder Hugo Kaboš.58

From Trnava to Lískovec

The first “Ocelový dom brand” buildings were constructed in Bratislava for the Cooperative of State Railway Employees [Družstvo štátnych zamestnancov a železničiarov]. This commission was taken over from the Metal and Wire Company; in total, 7 houses were contracted,59 mostly modest single-storey family houses. Two of them differed slightly, using an altered construction in which the space in the steel frame was infilled with brick, rather than remaining hollow as in the original Böhler system.60 The houses were built on Liptovská Street, where 5 of them remain to this day, though some with an altered appearance.

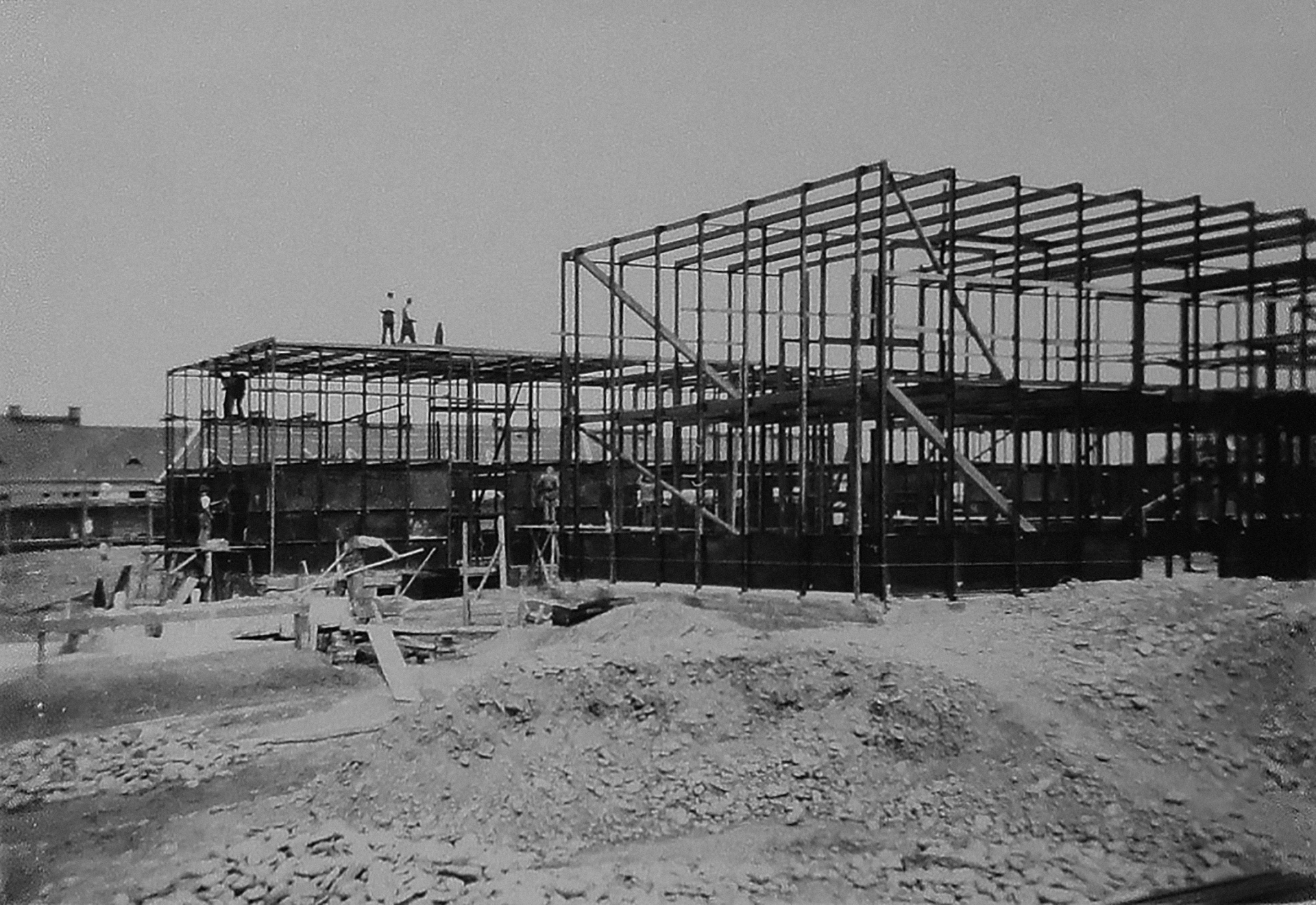

The next construction took place in Trnava. The Coburg Works allotted part of its factory area for a small office building as a kind of experiment; supposedly, the results were satisfactory and winter performance was good.61 More buildings soon followed, this time as living quarters for the factory workers; permission for their construction was requested in August 1929.62 This was the first Oceľový dom project of larger size, containing 8 small flats, 4 per floor. This structure also survives, although in poor condition, its Heraklith paneling peeking through the degraded plaster.

Meanwhile, more construction was going on in the Czech part of the state. The biggest commissioner was the Mining and Metallurgical Company, which needed housing for its workers, and naturally had an incentive to see Steel House succeed. Apartment houses similar to the one in Trnava were erected in the Silesia region: one in the town of Bohumín, one near the Hohenegger mine in Karviná and two at the Ignát mine in Ostrava. Another such apartment house was built in the town of Hlubočky, for the workers of the Moravia factory.63

By November 1929, after roughly a year of operation, a total of 21 steel houses had been built.64 Considering the ambitious plans, and the potential that prefabricated housing offered, the number was very small. Indeed, the company ended the year with a steep loss of 724 000 Kč.65 A chief cause was the price of the houses. Despite the promise of a cheaper alternative to traditional masonry, this proved untrue, and Oceľový dom had to offer the houses at uncompetitive prices if it wanted any profit from them at all.66 This turned into a bitter point of contention with Gebrüder Böhler, which insisted its building system was profitable.67 Oceľový dom considered switching to a different steel system, namely the Förster system which seemed cheaper,68 but ultimately the licensing agreement with Böhler prevented any definite decision from being taken.69 To make matters worse, the Austrian Böhler patent was later rejected in Czechoslovakia, making the licensing agreement with Böhler pointless; after a series of unfriendly letters, the two companies ultimately agreed to terminate all relations by 1931.70

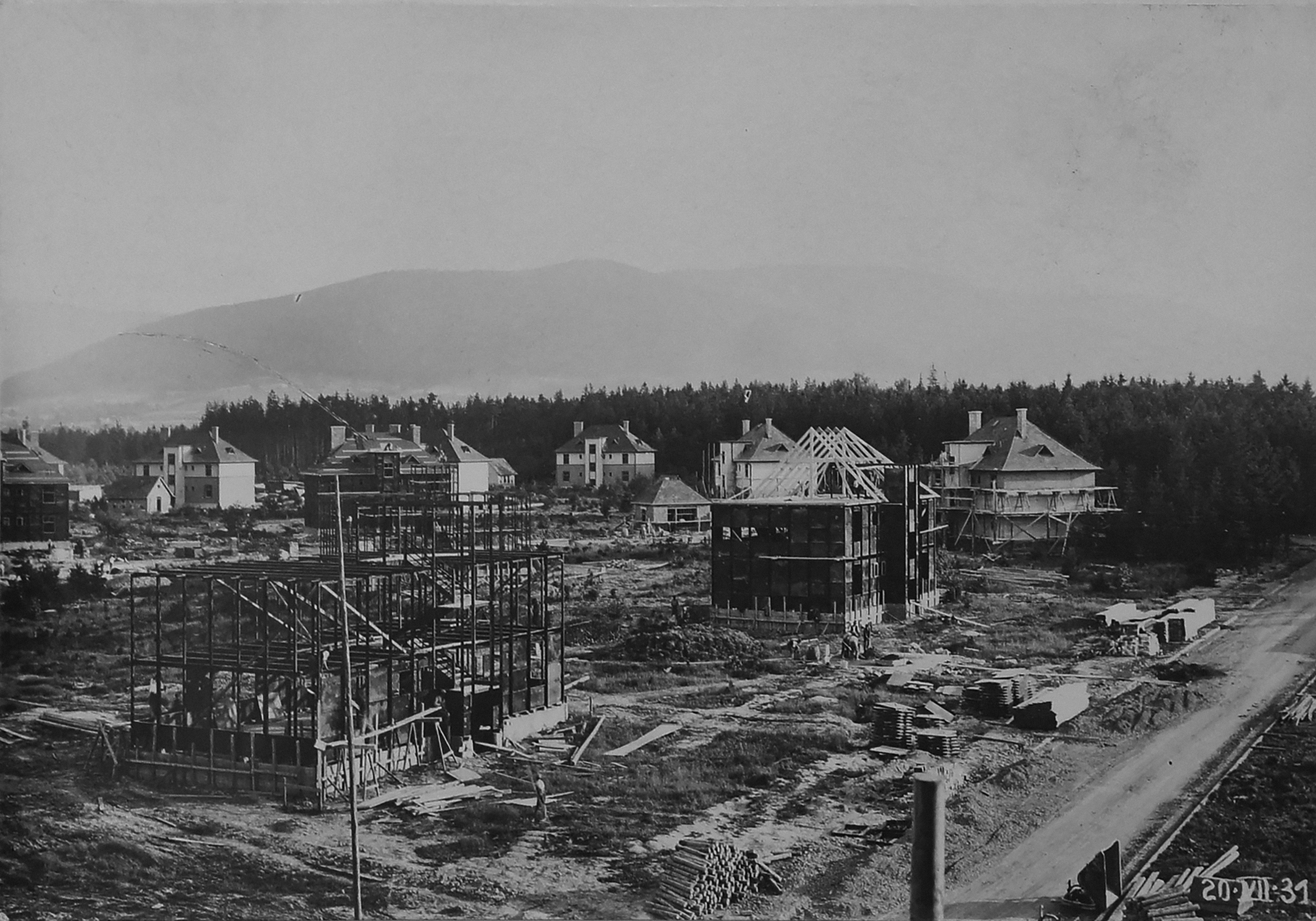

Under different circumstances, this switch could have allowed Oceľový dom time to adjust. But time was precisely what Oceľový dom now lacked. By 1930, the effects of the Great Depression were starting to show, and building with steel, already on the expensive side,71 found it difficult to stay competitive. The negotiations in several cities had gone nowhere; for example, the license with a builder in Moravská Ostrava was terminated because he had been unable to secure any commissions.72 Still, in 1930, hoping to turn events around, Oceľový dom secured the largest commission in its existence. The Mining and Metallurgical Company, for which it had built several houses earlier, needed more worker housing for its sheet-metal factory in Lískovec, on the outskirts of Frýdek-Místek (today part of the city). In total, 320 apartments were planned, split into two groups: half to be built with masonry walls, and half with steel. Naturally, the second group was entrusted to Oceľový dom.

Typologically, the houses in the colony were similar to the earlier two-story workers’ housing in Trnava; the difference being that the apartment houses were arranged in rows, not as freestanding blocks, and contained only 2 flats per floor instead of 4. Still, even these apartments were small, consisting of a living/sleeping room, kitchen, pantry, WC and a sloped-floor kitchen alcove that served for washing or occasional bathing. No standard bathroom was included. The houses had amenities such as electricity and plumbing but no central heating, and each room was heated with a separate stove. Because of this, the houses also had cellars where tenants could store coal and food.73 Thirty-two of these houses were built, arranged along a NE-SW axis in 4 generously spaced rows, plus 8 semi-detached apartment houses with slightly larger apartments, positioned perpendicularly along the two main roads. Supposedly, each row took less than three weeks to complete, much quicker than the parallel structures built with brick.74

This was the only project of Oceľový dom that gained wider publicity, and articles appeared in the journal Zprávy veřejné služby technické [Reports on Public Technical Services], as well as Architekt SIA.75 Even Slovenský staviteľ published photos, though without mentioning the company by name.76 It should be noted that earlier research mentions Bohuslav Fuchs as the author of the colony.77 There is indeed a letter from the Mining and Metallurgical Co. addressed to Fuchs mentioning “Your [Fuchs’] article about Lískovec in the journal Stavitel”, which would confirm his involvement.78 However, what Fuchs actually published in Stavitel was not an article, but his own plans for flat-roofed single-family row houses, very different from the colony built in Lískovec.79 The Mining and Metallurgical Co. selected the project in an invited competition; minutes from the jury’s evaluation show positive comments towards one project closely resembling the built result, while another project, which seems to fit Fuchs’ published images, was described by the jury as “unfitting”.80 Thus, while Bohuslav Fuchs was involved in the Lískovec colony, the actual extent of his involvement remains uncertain.

The End of a Vision

Despite this major success, the year 1930 signified another financial loss for Oceľový dom – 173 000 Kčs – making the total loss close to a million.81 With the Depression only deepening, the situation seemed dim, and the enthusiasm of Coburg was fading. Already by mid-1930, Coburg managers were voicing negative remarks about Oceľový dom and considered letting the company go.82 By 1931, all Coburg stocks were transferred to the Mining and Metallurgical Co., which, being closely tied with the company from the start, now became the majority shareholder.83 Reflecting this shift, Oceľový dom moved its headquarters from Bratislava to Prague in July 1931.84 In an attempt to throw the company a lifeline, the Mining and Metallurgical Co. commissioned Oceľový dom to build yet more workers’ housing for its steelworks in Třinec. This colony, dubbed “Canada”, consisted of 20 detached apartment houses, otherwise similar in size and style to those of Lískovec;85 it too survives to the present day. It was the second largest project that Oceľový dom ever built. Ultimately, it was also one of the last. Apart from one private villa, the Třinec housing was the only finished commission in 1931.86 The year ended in yet another loss; this time it was a crippling half million crowns, making the total loss close to 1.5 million – half of what the company had started with.87 In 1932, almost no income was registered, and the loss increased by another half million.88

With this development, Oceľový dom no longer made economic sense. After unsuccessful negotiations aimed at working with the Baťa company or providing steel skeletons for public buildings, such as the General Public Insurance Institute in Prague (which was ultimately built with reinforced concrete),89 the company fired most of its staff in 1932 and reduced activities almost to zero.90 It did not close down entirely however, hoping that the crisis would eventually pass and better futures would emerge. These wishes ultimately came true, but with a twist of dark irony. By the mid-1930s, the situation in Europe had changed. The fear of unemployment became less acute but was replaced by another – the fear of war. Yet from the perspective of steel producers, producers, the situation paradoxically brought hope. And so, in 1935, the dormant Oceľový dom awakened and returned to the scene – only this time not making any houses, but rather ammunition shells and gas-mask filters.91 The production took some time to set up, but it seemed to work well enough; ironically, it was only in this war-oriented capacity that Oceľový dom became profitable in 1938, for the first time since its founding.92 In the war years, it continued to operate freely, since it had moved its headquarters once again to Bratislava,93 now in the independent Slovak State. The company functioned during the entirety of the war, using a former Coburg factory in Pohorelá to make various arms supplies, steel containers and other items. The only production still related to construction was the licensed manufacture of “Lignos” wood-fibre insulation boards.94 When the war ended, the company was nationalized and merged with the Slovak Works for Enameled and Iron Goods [Slovenské závody na smaltovaný a železný tovar] in 194695 – bringing its history to an end.

The Steel Houses from a Technical Standpoint

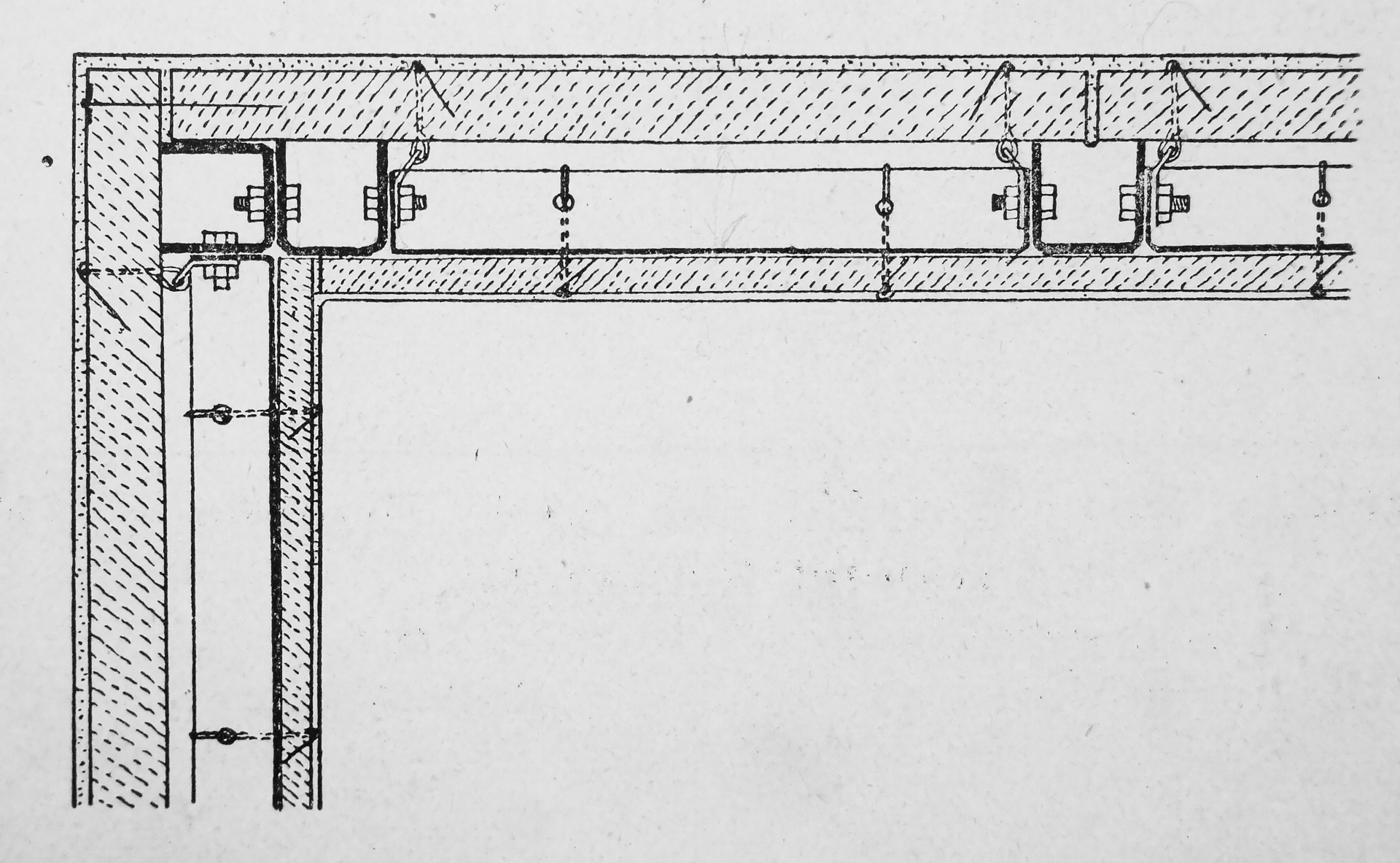

Oceľový dom’s Böhler buildings belong to the category of structures using a steel skeleton with non-load bearing cladding.96 As mentioned earlier, the structure consisted of steel U-posts, spaced 1 m apart, with an outer and inner cladding. Additionally, steel panels were attached to the inner side of the frame. These served primarily to give the structure stiffness and wind resistance, and secondarily, in the original design of Alfred Schmid, to create an inner surface, which could be painted, wallpapered or pressed with various decorative motifs. The outer cladding was made of 5-cm-thick plastered Heraklith boards, attached to the structure via short wooden studs inserted into the U-posts. Surviving houses such as the one in Trnava show that the plaster was applied onto a steel mesh, likely to prevent cracks where the Heraklith panels joined. However, the Metal and Wire Processing Works company innovated the design slightly, adding another, 2.5-cm-thick Heraklith layer to the inner side.97 Clearly, despite Schmid’s confident phrasing, the insulation capabilities of the original design were deemed insufficient. Thus, the final wall was a “sandwich” with an air cavity trapped between two Heraklith layers, plus the steel paneling. On the other hand, the air cavity was reduced from 10 to only 5 cm,98 bringing the total thickness of the wall to 15 cm (including plaster). This change could have been related to the ongoing discussions about the ideal thickness of air cavities, which tended towards this value, about 4–5 cm.99 But it might also have been simply the result of the wish to keep the wall as thin as possible after adding the second Heraklith layer.

Assuming the λ value of Heraklith at 0.082 W/mK,100 the U value of the complete 15 cm wall would be approximately 0.78 W/m2K. In theory, this is comparable to a plastered brick wall 90 cm thick, surprisingly close to what the advertisements boasted. However, this would only hold true on the condition that the air cavity was completely airtight; complaints about cracks in the plaster of finished houses show that this was not always the case.101 Also, compared to masonry, the wall had next to zero heat capacity: especially problematic in the case of local stove heating wherein heating ceases at night, thus allowing the structure to cool rapidly, with the risk of reaching the dew point. On the other hand, thanks to the double “sandwich” cladding of the steel frame, the design essentially eliminated thermal bridges, which were a major issue in the skeleton structures of the era – Walter Gropius’ 1927 steel house in Stuttgart, for example, suffered from extensive thermal bridges because it only had insulation between steel posts.102 Still, Oceľový dom remained somewhat unsatisfied with the Heraklith walls, as evidenced by letters inquiring about Calofrig and Lindbeton insulation materials.103 But these possibilities might also have been intended only to cut costs, as Heraklith ultimately remained the material of choice for all the buildings the company constructed. One problem, however, was the souterrain on which the steel structure rested – its concrete walls, often just 30 centimeters thick, had no insulation at all. There were complaints from tenants of the steel houses that liquids stored in the cellar repeatedly froze during winter.104

Inner partitions consisted of single-layer Heraklith panels inserted between steel posts and plastered, which remained unchanged from Alfred Schmid’s design. One would imagine that these 5 cm thick partitions would perform poorly in terms of acoustic insulation. But a change was made to the floors. In the original Böhler design, wooden beams were inserted into the U-shaped steel joists (the open side of the U facing up), onto which wooden planks were nailed, covered with ceramic tiles.105 But in the later Oceľový dom buildings, we see a different setup: corrugated steel sheets with a layer of concrete poured on top, a modern solution that remains commonplace in steel structures today. Yet contrastingly, rather archaic wooden beams and planks were then laid on top as covering, along with the reed-and-plaster suspended ceilings below.106 Another atavism can be found in the pitched roofs. Although one might guess they too would utilize structural steel, in fact they were never integrated into the system at all – in all the built houses, the roofs were a traditional timber structure. Evidently, the steel houses were not yet a fully industrialized, holistic building system that could take full advantage of the machine age at every step. They were a cutting-edge idea at the core with various ad-hoc traditional solutions added on. Yet such a method was anything but uncommon during the era, and no doubt the company would have kept innovating its technical aspects had it only survived longer.

Conclusion

The Oceľový dom company was an ambitious vision that quickly rose to seize its opportunity, but almost just as quickly flared out and disappeared into obscurity. A conservative estimate, using archival sources, would give us about 90 houses constructed in the roughly 3.5 years of the company’s operation107 – two-thirds of which are represented by the Lískovec and Třinec colonies: not a large number, even assuming a few dozen or so additional houses may have been lost to the historical record and remain unknown. One would imagine that a successful mass prefabrication operation would build hundreds, if not thousands of houses; the developments in Britain show that it was far from impossible. And recalling that the overwhelming majority of the houses were commissioned by the company that essentially owned Steel House, the whole project appears a complete failure.

Undoubtedly, the lack of success can be partially attributed to the Depression, which struck the company during its vulnerable infancy and prevented its growth when it was most needed. Yet this explanation nonetheless falls short. The Modernists, who in theory should have had every incentive to see such a project succeed, largely ignored it, seemingly because the houses stylistically catered to the broadest popular taste. Yet even the target audience remained indifferent. In Czechoslovakia, Oceľový dom was the first, but not the only such project: in the early 1930s, the architects Lev Krča and Stanislav Tobek developed modern-looking prefabricated steel houses for the Vítkovice Ironworks.108 A closer look at this attempt would provide a valuable comparison, but their ultimate fate was similar. It’s difficult to say if these projects failed because of the choice of structural steel, or because the very idea of prefabrication was doomed from the start. Ultimately, no similar project took off in interwar Czechoslovakia and prefabrication remained only a vision.

Colin Davies’ analysis perhaps holds relevance here, pointing out that prefabricated structures, lightweight and anonymous, contradict the archetypal image of the rooted, solid, durable and personal “dwelling” most of us hold – and as for the architects, challenge their sense of authorship and originality that they tend to guard jealously.109 Or perhaps the Modernists were right, and successful prefabrication was only possible in a socialist planned state – which, as we know in hindsight, managed to prefabricate on a massive scale. Still, some prefabricated house projects succeeded even in capitalist conditions, as evidenced by the American catalogue houses or the Böhler company in Austria. In the case of Oceľový dom, it may well have been poor timing – if it had perhaps emerged a few years sooner, there would have been hundreds of their steel houses today, not a few dozen.

Whatever the reason was, the story of Oceľový dom is part of the holy grail of prefabrication which allured both architects and industrialists for different reasons. Although involving some architects, Oceľový dom ultimately belongs to that second category of prefabrication: one motivated by pure business interests, rather than grand architectural visions. In the end, it was also pure business interests that brought Oceľový dom to its demise – a conclusion not unfamiliar to the various attempts at prefabrication that emerged during the 20th century.

This paper was supported by the Mobility Fund

of the Faculty of Architecture, CTU Prague.

Alexander Kuric

orcid: 0000-0002-5456-2848

Faculty of Architecture

Czech Technical University in Prague

Thákurova 9

160 00 Praha 6

Czech Republic

1 DAVIES, Colin. 2005. The Prefabricated Home. London: Reaktion Books, p. 11.

2 HERBERT, Gilbert. 1984. The Dream of the Factory-Made House. London, Cambridge, MA: MIT Press, p. 5; CANEPARO, Luca. 2014. Digital Fabrication in Architecture, Engineering and Construction. Dordrecht: Springer, p. 7.

3 LE CORBUSIER. 2007. Toward an Architecture. Los Angeles, CA: Getty Publications, p. 290.

4 GUILLÉN, Mauro F. 2006. The Taylorized Beauty of the Mechanical. Scientific Management and the Rise of Modernist Architecture. Princeton, NJ, Oxford: Princeton University Press, p. 14.

5 Herbert, G., 1984, pp. 4, 7, 9.

6 SMITH, Ryan E. 2010. Prefab Architecture: A Guide to Modular Deisgn and Constrction. New Jersey: John Wiley & Sons, p. 5.

7 Smith, R., 2010, p. 6; Davies, C., 2005, p. 48.

8 Davies, C., 2005, p. 44.

9 Davies, C., 2005, p. 51; Caneparo, L., 2014, p. 43.

10 Smith, R., 2010, p. 111.

11 Davies, C., 2005, p. 49.

12 Davies, C., 2005, p. 60.

13 MCGUINESS, John. 2017. Workers’/Affordable Housing and the Development of Construction Systems. Industrial Archaeology Review, 39(2), pp. 129–146. doi: 10.1080/03090728.2017.1404224; Herbert, G., 1984, pp. 20–21.

14 McGuiness, J., 2017.

15 Davies, C., 2005, p. 61.

16 Herbert, G., 1984, p. 69.

17 Herbert, G., 1984, p. 32.

18 Herbert, G., 1984, p. 36; Davies, C., 2005, pp. 132–133.

19 Herbert, G., 1984, pp. 67–68.

20 Herbert, G., 1984, p. 52.

21 Herbert, G., 1984, p. 97.

22 PROKOP, Ursula. 2009. Alfred Schmid. Architektenlexikon [online]. Available at: https://www.architektenlexikon.at/de/550.htm (Accessed: 13 December 2024).

23 Herbert, G., 1984, p. 74.

24 SCHMID, Alfred. 1927. Wohnhäuser nach dem Stahlwandsystem. Zeitschrift des Österreichischen Ingenieur- und Architekten-Vereines, 79(19–20), pp. 174–176.

25 Das Österreichische Bauwesen. 1928. Wien: Wirtschafts-Zeitungs-Verlags-Gesellschaft, p. 61.

26 Herbert, G., 1984, p. 74.

27 Herbert, G., 1984, pp. 75, 78, 182.

28 ONDŘEJ, Severin. 1923. Používání betonu při stavbě obytných budov a vývoj této otázky. Prague: Klub architektů. This book represents an early exhaustive list of all domestic and foreign made cinder concrete blocks.

29 KURIC, Alexander.

2023. Calofrig: The Miraculous Material of Interwar Czechoslovakia. In: 12th ACAU 2023: Proceedings of 12th International PhD Students Conference. Brno, 8 November 2023. Brno: Brno Technical University, pp. 18–29.

30 FOUSEK, F. 1927. Budeme stavět laciněji? Národní listy, 25 December, p. 6; Venkov. 1929. Ideální, nejlacinější stavivo: železo a – vzduch. Venkov, 12 July, p. 5.

31 Lidové noviny. 1928. Ocelové domy. Jejich výhody a nevýody. Budou se stavět ocelové domky také u nás? Lidové noviny,

1 September, p. 7.

32 Hlídka. 1926. Bytová nouze. Hlídka, 43(4), pp. 197–198.

33 Correspondence between Böhler and the later company Oceľový dom mentions a previous licensing agreement with the Metal and Wire Processing Works. See: Agreement on the production of steel houses in Czechoslovakia, 1929. Inv. no. 3, box 1, Oceľový dom, úč. Spol. State archive in Bratislava.

34 They included Slovak, Czech and German newspapers, specifically: Považské hlasy, Trenčan, Slovák, Slovenský denník, Gemer Malohont, Robotnícke noviny, Slovenský východ, Národný denník, Lidové noviny, Preßburger Zeitung.

35 For the most detailed of these articles, see: Preßburger Zeitung. 1927. Das erste Stahlhaus in Preßburg. Preßburger Zeitung, 11 December, p. 3; Prager Presse. 1928. Das erste Stahlhaus in der Tschechoslovakei. Prager Presse, 17 January, p. 5.; Lidové noviny. 1927. Böhlerův ocelový dům. Lidové noviny, 11 December, p. 7. Two articles put the price as 35 000 Kčs, and one as 45 000 Kčs.

36 Architekt SIA. 1928. První ocelový domek v Praze. Architekt SIA, 27, p. 87. This figure would make it more expensive than masonry alternatives. A 1925 catalogue of cheap houses prices similarly sized houses between 40 000 – 50 000 Kčs; a 1928 book puts a 3-room + kitchen house at 60 000 Kčs. (See KELLER, Jindřich. 1925. 80 vzorných návrhů levných rodinných domků a vil. České Budějovice: O. Rosín; NOVÁK, Josef. 1928. Jak si postavím levně domek. Ruda nad Moravou: J. V. Mangl.)

37 See for example: Šťastný domov. 1928. Ocelový domek. Šťastný domov, 23(11), pp. 212–213; Večerní list. 1928. Nový praktický plán k odpomoci bytové nouze. “Ocelový dům” v Praze. Večerní list, 5 April, p. 5; Lidové noviny. 1928. První ocelový dům v Praze. Lidové noviny, 5 April, p. 3.

38 The pattern of architects dismissing this kind of progressive technology clad in traditional clothes as non-architecture is well described by Davies, C., 2005, pp. 25, 193.

39 Architekt SIA. 1928. První ocelový domek v Praze. Architekt SIA, 27, p. 87; Stavební rádce. 1928–1929. První ocelový dům v Praze. Stavební rádce, 1(2), p. 20.

40 This was in line with the general spirit of the book, which took a positive stance towards all of the novel building systems. See Novák, J., 1928, p. 53.

41 NĚMEC, Zdeněk. 1967. Rudné baníctvo na Slovensku v rokoch 1918–1938. Bratislava, Košice: Východoslovenské múzeum v Košiciach, p. 60. Němec puts the year as 1929, however articles from late 1928 already mention the Steel House company (see note 45).

42 Němec, Z., 1967, p. 51.

43 Němec, Z., 1967, p. 54.

44 Letter from Max Fejér. 1. 6. 1928. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Letter to Otokar Kruliš-Randa. 28 .7. 1928. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

45 Prager Presse. 1928. Konstituierung der tschechoslovakischen Stahlhaus A.G. in Bratislava. Prager Presse, 7 October, p. 8.

46 His name was Alexander Fazekas. See: Prager Presse. 1928. Konstituierung des Verwaltungsrates der “Stahlhaus” A.G. in Bratislava. Prager Presse, 7 October, p. 12.

47 These were Max Fejér and Ján Tille. See Zápisnica o zasadaní správnej rady dňa 28. 9. 1928. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava; Zápisnica napísaná na schôdzi správy zo dňa 27. 6. 1928. Inv. no. 33, box 9, Účastinárska spoločnosť, predtým Coburg, banské a hutné závody v Bratislave. State Archive of Bratislava.

48 Stanovy Ocelový dom úč. spol. 28. 7. 1928. Inv. no. 1, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

49 Zápisnica o zasadaní správnej rady dňa 28. 9. 1928. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

50 Ocelové domky systém Böhler. Obydlí budoucnosti. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

51 The smallest flats consisted of a room, a kitchen and a toilet. See plans in: Stavební dokumentace obytných budov KH. Inv. no. 124, box 113, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

52 There is one photograph of an atypical, Modernist-looking finished house with a flat roof in the company archives. However, no exact location or description is provided, and the text records never mention such a house. See: Ocelový dům – snímky. Inv. no. 7399, box 1669, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

53 Zápisnica o zasadaní správnej rady dňa 6. 6. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

54 EGRI, Viktor. 1928. Acélházak Szlovenszkón. Prágai Magyar Hirlap, 18 November, p. 12.

55 TILLE, Jan. 1928. Stavby domů z oceli. Hospodářská politika, 2(42), p. 726. For other examples see: RAJSKÝ, Ing. 1928. Zlevnění stavby domů používáním ocele. Tribuna, 28 October, p. 7; Slovák. 1928. Ocel ako materiál k stavbe domov. Slovák, 30 October, p. 35.

56 Letter to Vladimír Weiss. 11. 5. 1932. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

57 Zápisnica o zasadaní správnej rady dňa 3. 7. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava; Zápisnica o zasadaní správnej rady dňa 15. 7. 1930. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

58 Zápisnica o zasadaní správnej rady dňa 27. 11. 1928. Inv. no. 2, box 1, Fond Oceľový dom, úč. spol. State Archive of Bratislava.

59 Letter to Alexander Fazekas. 23. 7. 1928. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

60 This system was developed by the appropriately named Ing. Cihla (“Brick”). Zápisnica o zasadaní správnej rady dňa 3. 7. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava. See photos in: Ocelový dům – snímky. Inv. no. 7399, box 1669, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

61 Založenie fy Ocelový dom, Bratislava, 21. 6. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

62 OSYKOVÁ, Linda. 2023. Who Formed the Architectural Appearance of Trnava in the Years 1918 – 1945? Architektúra & urbanizmus, 57(1–2), pp. 136–148. doi: 10.31577/archandurb.2023.57.1-2.10

63 Zápisnica o zasadaní správnej rady dňa 3. 7. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava; Bilanz der Stahlhaus A.G. Bratislava zum 31. Dezember 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava. Some of the Silesia buildings were also mentioned in: MYSLIVEC, Theodor. 1929. Bytová péče a jiná blahobytná zařízení ostravsko-karvinského revíru. In: Kamenouhelné doly ostravsko-karvinského revíru. Moravská Ostrava: Ředitelská konference ostravsko-karvinského kamenouhelného revíru, pp. 265–516.

64 Zápisnica o zasadaní správnej rady dňa 27. 11. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava; Zpráva správy. Zápisnica napísaná dňa 21. 10. 1931 na riadnom valnom zhromaždení v Bratislave. Inv. no. 47, box 11, Účastinárska spoločnosť, predtým Coburg, banské a hutné závody v Bratislave. State Archive of Bratislava.

65 Lidové noviny. 1930. Ocelový dům. Lidové noviny, 29 May, p. 9; Hlavná kniha od 31. aug. 1928 do 31. decembra 1935. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

66 Letter to the Mining and Metallurgical Company, 18. 11. 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

67 Letter from Gebr. Böhler AG, 4. 6. 1929. Inv. no. 3, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

68 Zápisnica o zasadaní správnej rady dňa 8. 1. 1929. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

69 Zápisnica o zasadaní správnej rady dňa 13. 5. 1930. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

70 Letter to Gebr. Böhler AG, 19. 8. 1929. Inv. no. 3, box 1, Oceľový dom, úč. spol., State Archive of Bratislava; Letter to Gebr. Böhler AG, 10. 4. 1930. Inv. no. 3, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

71 This factor was admitted even by technical experts with a pro-steel attitude. See PATTA, Emil. 1929. Ocel a plávkové válcované železo profilové jako samostatný materiál konstruktivní u obytných staveb. Architekt SIA, 28(12), pp. 251–259.

72 Zápisnica o zasadaní správnej rady dňa 15. 7. 1930. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

73 POLÁŠKOVÁ, Jiřina and POLÁŠEK, Jaromír. 2022. Domy v koloniích Lipina a Berlín vznikaly z oceli a plechu. Zpravodaj města Frýdku-Místku, (3), pp. 22–23 [online]. Available at: https://www.frydekmistek.cz/wp-content/uploads/2022/05/1647870914-fm-03-2022-web.pdf (Accessed: 13 December 2024); KANCNÝŘ, Karel. 1931. Ocelové domy dělnické kolonie v Lískovci u Frýdku. Zprávy veřejné služby technické, 13, pp. 239–241; Architekt SIA. 1931. Kolonie ocelových domků. Architekt SIA, 30(1), p. 20.

74 Kancnýř, K., 1931.

75 Kancnýř, K., 1931.

76 Slovenský staviteľ. 1933. Ukážka oceľových stavieb – Mostáreň v Karlovej Huti – Stavba oceľového domu. Slovenský staviteľ, 3(10–12), pp. 143, 145, 147.

77 Polášková J. and Polášek, J., 2022; ZLÁMALOVÁ, Aneta. 2011. Architektura a urbanismus Frýdku-Místku, 1900–1943. Master’s thesis. Faculty of Arts, Palacký University, Olomouc. Available at: https://theses.cz/id/qjn6xj/ (Accessed: 13 December 2024).

78 Letter to Bohuslav Fuchs. 19. 8. 1930. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

79 FUCHS, Bohuslav. 1930. Dělnická kolonie v Lískovci. Stavitel, 11, pp. 41, 89.

80 Bemerkungen zu den einzelnen Projekten des Wettbewerbes für die Arbeiterkolonie in Lískovec. Inv. no. 124, box 113, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

81 Lidové noviny. 1931. Ocelový dům. Lidové noviny, 1 July, p. 12; Hlavná kniha od 31. aug. 1928 do 31. decembra 1935. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

82 Letter to the director of the Mining and Metallurgical Company, 19. 7. 1930. Inv. no. 102, box 23, Účastinárska spoločnosť, predtým Coburg, banské a hutné závody v Bratislave. State Archive of Bratislava.

83 Hospodářský archiv. 1932. Báňská a hutní společnost. Hospodářský archiv, 11(22), p. 164; Zápisnica o valnom zhromaždení zo dňa 13. 7. 1931. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

84 Zápisnica o valnom zhromaždení zo dňa 13. 7. 1931. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

85 Letter to Třinec Steelworks. 8. 5. 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

86 Účet rozvažný k 31. prosinci 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

87 Lidové noviny. 1932. Ocelový dům. Lidové noviny, 6 July, p. 11; Hlavná kniha od 31. aug. 1928 do 31. decembra 1935. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

88 Hlavná kniha od 31. aug. 1928 do 31. decembra 1935. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

89 Schůze správní rady akciové společnosti Ocelový dům dne 3. listopadu 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Letter to the Mining and Metallurgical Company. 11. 7. 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

90 Účet rozvažný k 31. prosinci 1932. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

91 Ředitelská zpráva pro schůzi správní rady 13. 2. 1935. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

92 Schůze správní rady 31. 5. 1939. Inv. no. 2, box 1, Oceľový dom, úč. spol. State Archive of Bratislava.

93 Slovenský denník. 1935. Oznámenie. Slovenský denník, 27 November, p. 6.

94 Ředitelská zpráva pro schůzi správní rady 13. 2. 1935; Adresár priemyslu, obchodu, remesiel, peňažníctva, poisťovníctva a družstevníctva na Slovensku. 1943. Bratislava: Obchodná a priemyselná komora, p. 38.

95 Vyhláška ministra priemyslu zo dňa 7. marca r. 1946. Inv. no. 35, box 5, Oceľový dom, úč. spol. State Archive of Bratislava.

96 Other examples are the British Tappan system, and the German Braune & Roth, Kästner, Stahlbau and Heka systems. See: Patta, E., 1929.

97 První ocelový domek v Praze. 1928.

98 Compare Patta, E., 1929 and Kancnýř, K., 1931.

99 MACHEK, Jan. 1931. Přecházení tepla a tepelná isolace ve stavitelství. Prague: Česká matice technická.

100 ERBEN, Adolf. 1944. Stavební isolace. Prague: Ústav pro učebné pomůcky průmyslových a odborných škol, p. 98.

101 Letter to Jan Pohl. 18. 9. 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha.

Regional Archive of Opava. Apparently, later tenants complained of insufficient insulation of the houses. See Polášková, J. and Polášek, J., 2022.

102 TOMLOW, Jos. 2006. Building Science as Reflected in Modern Movement Literature. In: Climate and Building Physics in the Modern Movement. Löbau, 24–25 June 2005. Zittau,Görlitz: Docomomo International, pp. 6–26.

103 Letter to the Calofrig company. 9. 7. 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Letter to Václav Havel. 9. 7. 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

104 Ocelový dům na jámě Ignát. 11. 7. 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

105 Patta, E., 1929.

106 VENCLÍK, Ing. 1930. Poznámky k použití ocelových nosných konstrukcí v pozemních stavbách. Architekt SIA, 29(12), pp. 240–242.

107 Bilanz der Stahlhaus A.G. Bratislava zum 31. Dezember 1929. Inv. no. 2712, box 573, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Účet rozvažný k 31. prosinci 1930. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Účet rozvažný k 31. prosinci 1931. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Účet rozvažný k 31. prosinci 1932. Inv. no. 2712, box 574, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava; Ocelový dům – snímky. Inv. no. 7399, box 1669, Báňská a hutní společnost, generální ředitelství Praha. Regional Archive of Opava.

108 Stavební rádce. 1933–1934. Typové montované domky. Stavební rádce, 6, p. 74; SVOBODA, Petr and LOUTOCKÁ, Vlasta. 2020. Lev Krča a Stanislav Tobek, tvůrci (nejen) sokoloven. Brno: Národní památkový ústav. Available at: https://www.vila-stiassni.cz/cs/lev-krca-a-stanislav-tobek (Accessed: 13 December 2024).

109 Davies, C., 2005, p. 110.

DAVIES, Colin. 2005. The Prefabricated Home. London: Reaktion Books, p. 11.

HERBERT, Gilbert. 1984. The Dream of the Factory-Made House. London, Cambridge, MA: MIT Press, p. 5; CANEPARO, Luca. 2014. Digital Fabrication in Architecture, Engineering and Construction. Dordrecht: Springer, p. 7.

LE CORBUSIER. 2007. Toward an Architecture. Los Angeles, CA: Getty Publications, p. 290.

GUILLÉN, Mauro F. 2006. The Taylorized Beauty of the Mechanical. Scientific Management and the Rise of Modernist Architecture. Princeton, NJ, Oxford: Princeton University Press, p. 14.

DOI: https://doi.org/10.31577/archandurb.2025.59.1-2.7

This work is licensed under a Creative Commons Attribution 4.0 International License